Welcome to Santa Pod Raceway

Home of the FIA European Drag Racing Championships, the fastest & loudest motorsport on Earth!

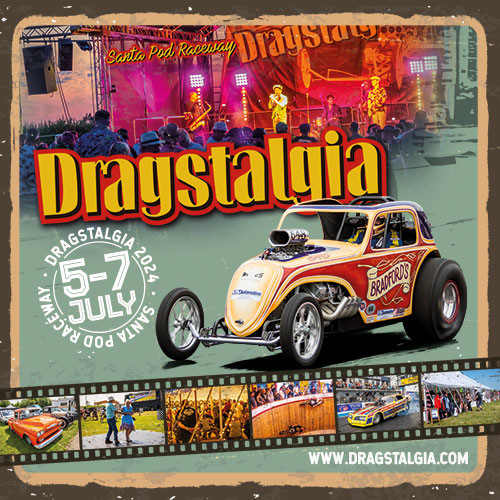

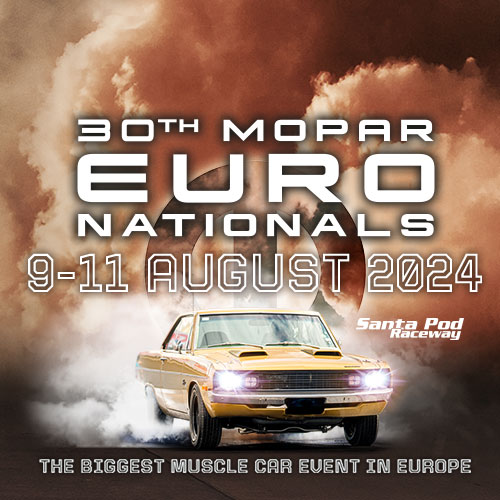

Santa Pod is the UK's most action-packed venue, hosting over 60 events annually including: Drag Racing, Modified Car Shows, VW Beetle & Campervan Festivals, Japanese Performance Car Shows, Retro & Classic Car Shows, plus Run What Ya Brung (RWYB) and Drift What Ya Brung (DWYB) public track days.

Enjoy VIP / Corporate Hospitality and fantastic family days out in the heart of England (on the border of Northamptonshire and Bedfordshire) and see Top Fuel Dragsters, Jet Cars, Monster Trucks, Drifting, Stunt Displays, Live Music and much more.

The full 2024 calendar of events is available on the Calendar pages: All Dates | Major Event Dates Only | RWYB Dates Only | DWYB Dates Only.

If you're a 'Pod regular you can add the Santa Pod calendar to your Google / iCloud Calendars.

Throughout the year

Throughout the year

Tickets & Merchandise

Buy tickets to Santa Pod Raceway events at www.SantaPodTickets.com or phone Box Office on 01234 782828.Santa Pod merchandise is available at www.SantaPodShop.com.

Santa Pod TV

Watch the latest videos from Santa Pod Raceway on SantaPodTV including Event Livestreams and Highlights videos at SantaPod.TV.

Follow Santa Pod Raceway

Keep up to date with Santa Pod Raceway on your favourite social media platform.

Mailing List

Fill out your e-mail address on the Newsletter page to receive the Santa Pod Email News Letter.